ClimaLevel multi-floor

Thermal screed activation

Photo @ Kemmer

Cooling with the ClimaLevel Multiboden

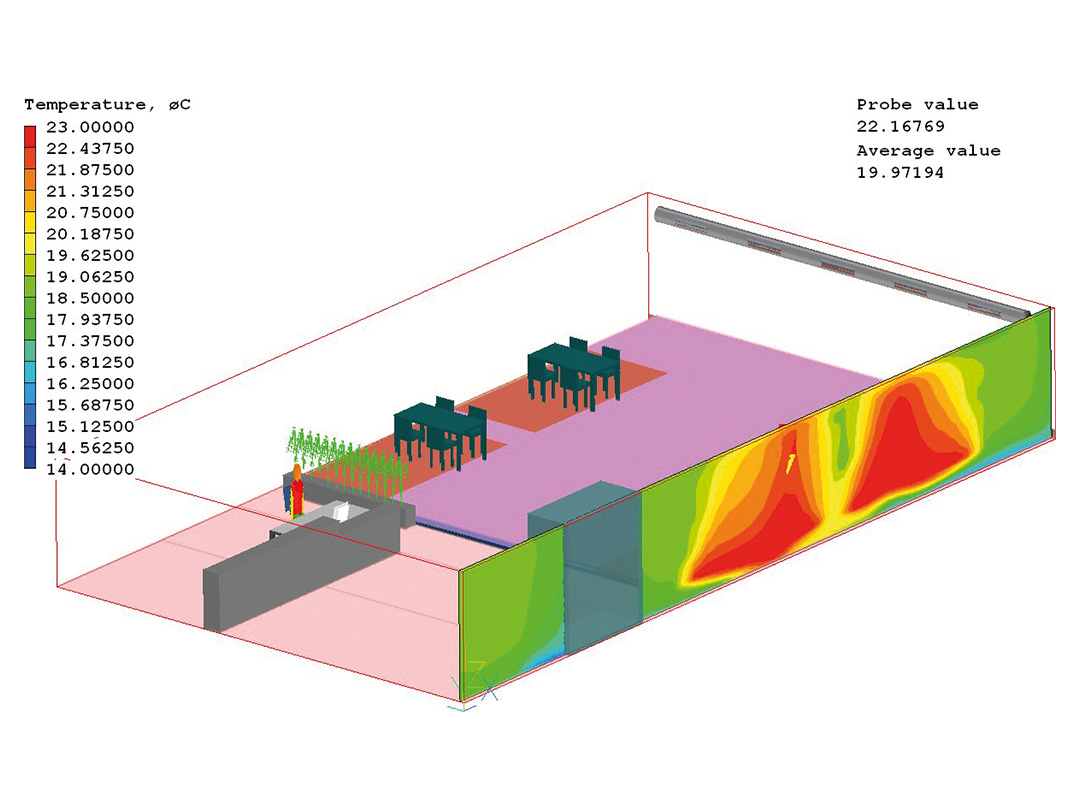

In the early 2000s, developments in architecture with large glass surfaces and denser building envelopes meant that the cooling of office and residential buildings became increasingly important. In principle, conventional underfloor heating systems can also be supplied with cold water to achieve a certain cooling effect. However, the so-called “cold air lake” reduces performance compared to the heating case. This is because there is almost no convective heat transfer in cooling mode. The overall heat transfer coefficient αFloor, which is approx. 11 W/m2 K in heating mode, is reduced to just 6 to 7 W/m2 K in cooling mode. Compared to normal floor cooling, the ClimaLevel Multiboden offers the “booster effect” by introducing the supply air close to the floor. The supply air flow in the area of the windows ensures the dissolution of the cold air lake and a significantly improved convective heat transfer in cooling mode. Without taking into account the lower temperature of the incoming supply air, cooling capacities of around 50 to 60 W/m2 can be achieved with the ClimaLevel Multiboden. This approach is the result of years of measurements and operating experience in our own “ClimaLevel Salon” as well as TRNSYS simulations by external service providers.

System planning

The cold water temperatures required to supply the system are 16-18°C. This makes it easier to combine with regenerative cooling systems, such as geothermal probes, cooling via groundwater or with heat pumps. As with conventional underfloor heating, individual room control is purely via the mass flows of the heating/cooling circuits on the water side. When determining the cooling capacity, the capacity required to dehumidify the supply air must be taken into account in addition to the pure cooling load. The planning of the central ventilation system is based on the minimum outside air rate.

Air flow and comfort

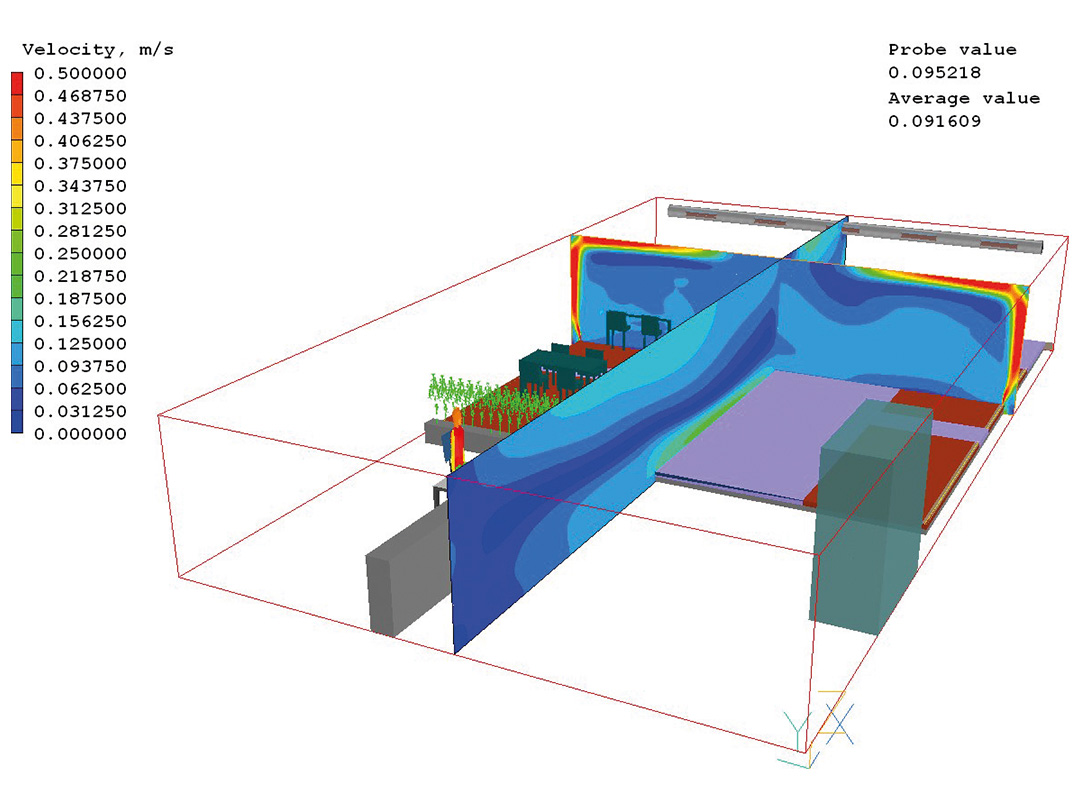

With the ClimaLevel Multiboden, the thermally treated and filtered supply air flows into the room through floor air outlets. By placing them in front of the windows, we create a veil of warm air in front of the cold window surfaces in winter. The LLE slotted rails used for this are a joint development by ClimaLevel Energiesysteme and Krantz GmbH from Aachen. As part of the development process, these rails were optimized in the Krantz GmbH flow laboratory with regard to sound power level and flow behaviour. The aim of the supply air flow is so-called turbulent mixing ventilation. On the one hand, it delivers quite high air velocities directly at the outlet, but at the same time also meets the highest comfort requirements with regard to room air velocities. According to DIN EN ISO 7730, an average indoor air velocity of 0.12 m/s would be permissible for category A under the given boundary conditions (dream = 24°C, T supply air = 20°C). The actual measured indoor air velocities were 0.10 m/s at one point, all other values were < 0.08 m/s. User surveys revealed an exceptionally high appreciation of the comfort provided by the system.

Passive cooling

If the ventilation is operated purely in outside air mode during the night, the air flow of the system integrated into the floorThe air flow of the system integrated into the floor simply cools the rooms at night – passive cooling: this cools down the storage mass of the floor and the room, which have heated up during the day.

Photo @ ???

Photo @ ???